Aluminium Composite Panel

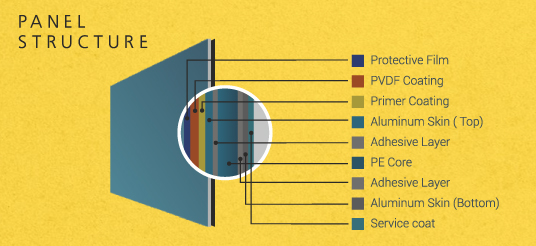

Aluminium composite panels (ACP), made of aluminium composite material (ACM), are flat panels consisting of two thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are frequently used for external cladding or facades of buildings, insulation, and signage.

Introduction

Aluminium composite panels (ACP), made of aluminium composite material (ACM), are flat panels consisting of two thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are frequently used for external cladding or facades of buildings, insulation, and signage. Wonder ACPs are created with extreme care to ensure superiority over competitive brands. Stringent measures are taken to make sure that Wonder quality surpasses international standards. At every stage, from the sourcing of raw material to creating the finished product, quality is the keyword. Tests are conducted as per the ASTM, AAMA and IS standards to guarantee that we deliver superior quality products. The top and the bottom layers of ACP panels are of coated aluminium sheets and the core sandwiched between them is polyethylene.Features

The unique properties of the aluminum composite panel determine its wide range of uses, involving engineering, large-scale building wall decoration, decoration of shopping mall facades, placards, stations, airports, display stands, ceilings, pillars, counters, furniture, telephone booths, elevators, factory wall materials, etc.

These structures made optimal use of ACP through its cost, durability, and efficiency. Its flexibility, low weight, and easy forming and processing allow for innovative design with increased rigidity and durability. Where the core material is flammable, the usage must be considered. The standard ACP core is polyethylene (PE) or polyurethane (PU). These materials do not have good fire-resistant (FR) properties unless specially treated and are therefore not generally suitable as a building material for dwellings; several jurisdictions have banned their use completely.

Application

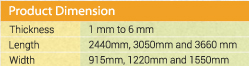

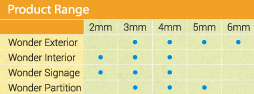

Technical Specification